Doxford Opposed Piston Oil Engine

The Nem-Stop used on some Doxford engines

Authored by: Alfons Verheijden

Pictures by: Various Sources

When a large motor ship has to be stopped as soon as

possible, it is desirable to get the engine running in the astern direction

quickly, but owing to the heavy "drag" on the propeller, this operation presents

difficulties.

One method of assisting this operation is to apply some

form of braking to the propeller shaft so that its rotation is stopped;

the

engine can then be started in the astern direction, which is usually a much

simpler proposition than starting in the astern direction from the condition of

ahead rotation.

The NEM-STOP arrangement, developed by the "North Eastern

Marine Engineering Co", and for wich patents have been applied, provides a

simple and efficient method of braking such engines.

The method adopted

is the use of partial decompression and comprises shutting off the fuel supply

to the engine and allowing

part of the air charge in the cylinder to escape

through a special relief valve during the compression and expansion strokes.

By this method, a net braking effect is obtained during each cycle of engine

operation, during the expansion stroke

there will be less air in the

cylinders to expand and counteract the braking effect of the compressin stroke.

The control valve consists of a steel block having three connections, i.e.,

compressed air from the starting air system,

compressed air to the special

cylinder relief valves and a connection giving release to atmosphere.

Two valves are fitted in the block. One valve, when open,

supplies compressed air to the relief valves, the other,

when open, allows

the air to escape from the relief valves to atmosphere; only one of the valves

is open at a time.

The control valve is operated by the engine Reversing

Lever, and when the lever is in the ahead or the astern position, the cylinder

relief valves are closed. When the lever is in "mid position", however, the

relief valves are lifted and allow partial decompression in the manner

described.

A diagram of the NEM-STOP is shown, operation

of it, is as follows:

1) Engine running

and normal manoeuvring.

The Nem-Stop

lever should be in in position "1", when all relief valves are shut and

function normally.

2) Using

Single-stage Nem-stop for stopping the engine.

The fuel is

first shut off, then the Nemstop lever placed in position "2", whereupon

all relief valves are held open and, due to the continuous escape of air

on both compression and expansion strokes, a net braking effect is

obtained.

This quickly stops the engine even though

the compression pressure which resists rotation of the engine is

reduced.

3) Using Two-stage Nem-Stop for stopping the

engine.

This is used when the engine has a

tendency to crawl with the gear, as before in position "2".

When this occurs the Nem-Stop lever is moved to positon "3", when full

compression is restored in cylinders 3 and 5, the immediate increase in

resistance during the compression being sufficient to stop the engine.

4) Use of the

Nem-Stop gear for scavenging combustion spaces after long "stand by"

periods.

The usual procedure is to open the

indicator cocks and give the engine a turn on starting air.

Nem-Stop gear can be used for this purpose by placing the lever in

position "2" and applying starting air.

The engine will then

turn very slowly and a good scavenging action is obtained through the

relief valves.

5) An additional

advantage claimed for the gear is that the engine can be quickly stopped

to prevent consequent damage should any defect develop in the running

gear and services when running at full speed. |

|

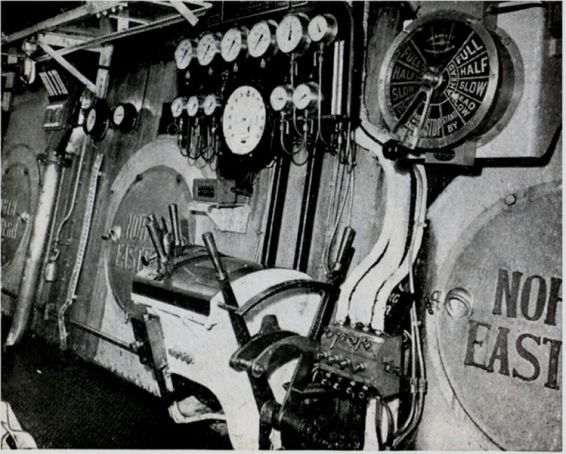

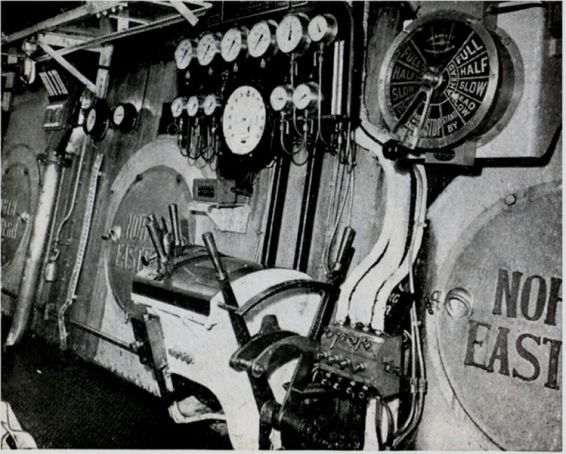

Right:

On engines with "Timing Valves" only the Nem-Stop handle!

Below:

With Reversing handle + Nem-Stop handle, on LB and LBD

Doxford"s, on which the forward Camshaft has to be changed during

manoeuvring from Ahead / Astern v.v. |

|

|

|

| |

|

|

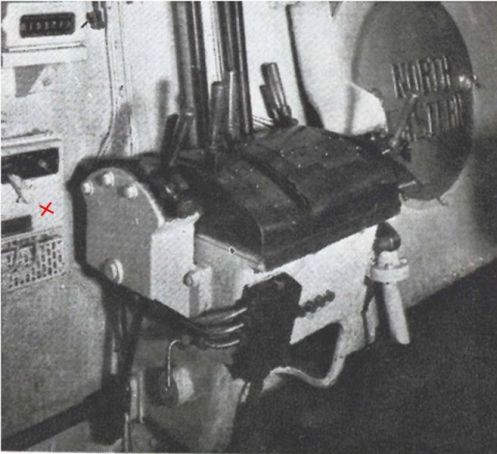

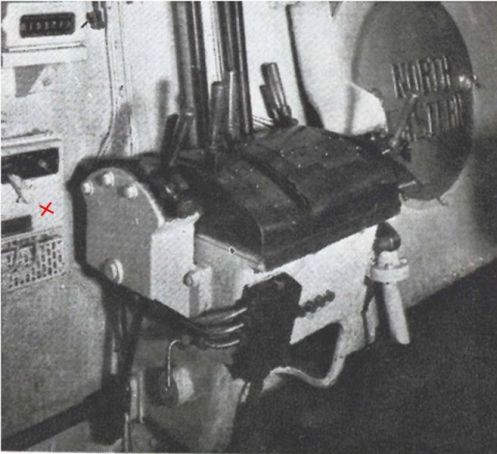

| The Special RELIEF VALVE used with

a NEM-STOP |

1954: "BRITISH VISION", 16000 Tons Tanker for the British

Tanker Co, with North Eastern Marine DOXFORD, type 67LB6, Stroke 2,320 mm, 6,800

b.h.p. at 119 r.p.m.

During Sea trials of the "BRITISH VISION" comparative

stopping test were carried out, and it was shown that the engine under normal

conditions, without braking, was stopped in 4 min. 45 sec., wheras with Nem

-Stop braking as described, it was stopped in 50 sec.; this test also

demonstrated that the use of Nem-Stop equipment reduced the time of stopping the

vessel by over than 2 minutes.

Back to the Doxford area